“Achievement of business performance by the partent company through bullying suppliers is totally alien to the spirit of the Toyota Production System.”

Taiichi Ohno

A Part is Not a Part, and A Supplier is Not a Supplier

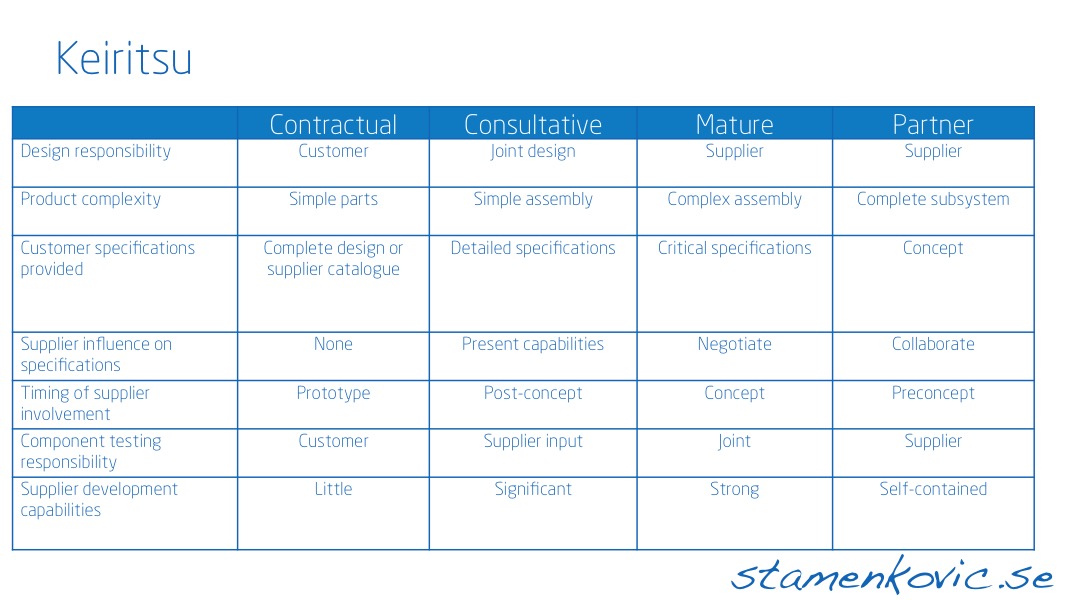

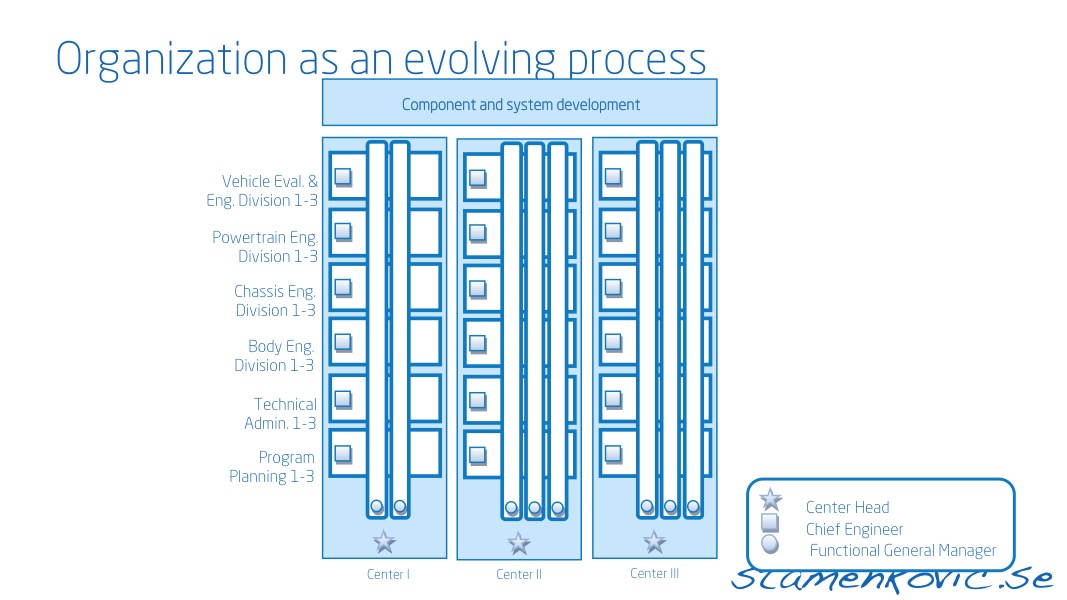

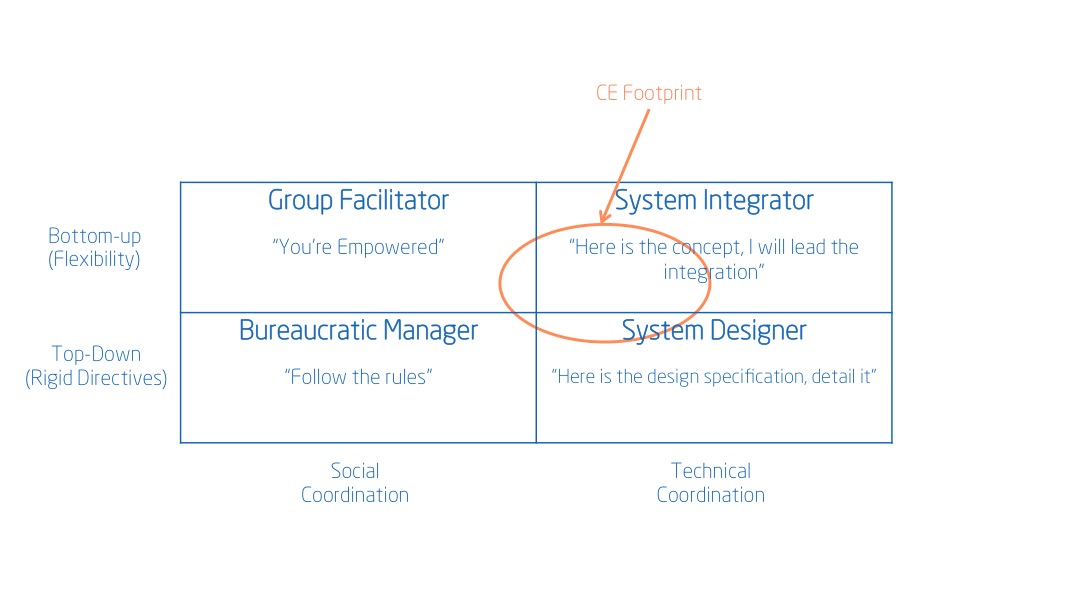

When customers buy cars, they do not care who makes the engine, radio, seat, carpet, etc. they want and expect reliable quality and hold the automaker totally accountable for anything that is not up to their expectations. Toyota recognizes this and makes sure that every car part reflects Toyota quality. To achieve this and makes sure that every car part reflects Toyota’s PD process and lean logistics chain.

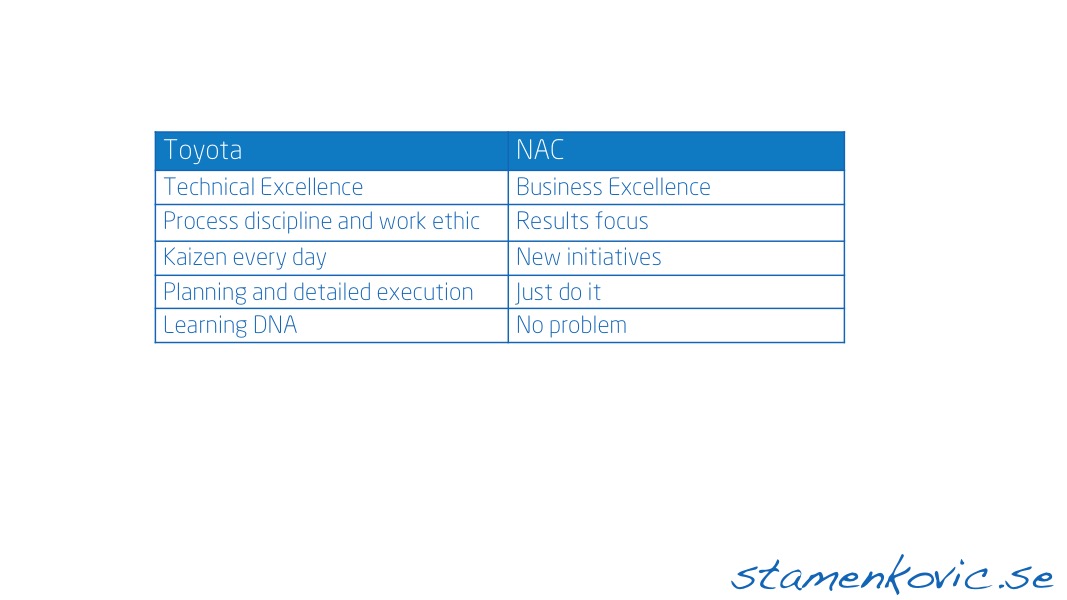

Other companies largely failed in emulating the Toyota model because they have not grasped the concept of true partnering. When the market gets though and there are serious earnings pressures, they have been less than forthright with suppliers, vacillating between public statements of commitment to partnership and trust and then unilaterally cutting supplier prices after signing contracts. They have even cut off suppliers in the middle of contract, resourcing it to a lower bidder. Toyota (as the supplier’s most demanding customer) to the contrary works on improving the supplier’s efficiency. For example when Toyota noticing that they were paying suppliers for many key parts above the lowest prices competitors paid globally, it issued a new target for all key suppliers as part of a program. The new program asked suppliers to reduce prices by 30 percent for the next model line; typically this would over a period of about three years.

Continue reading →