Where good ideas come from

professional lean, agile & change coach

“Engineers at the Toyota Technical Center use hetakuso-sekke, which is the small booklet containing the failures experienced in the past.”

Kunihiko Masaki, former President of Toyota Technical Center, Ann Arbor

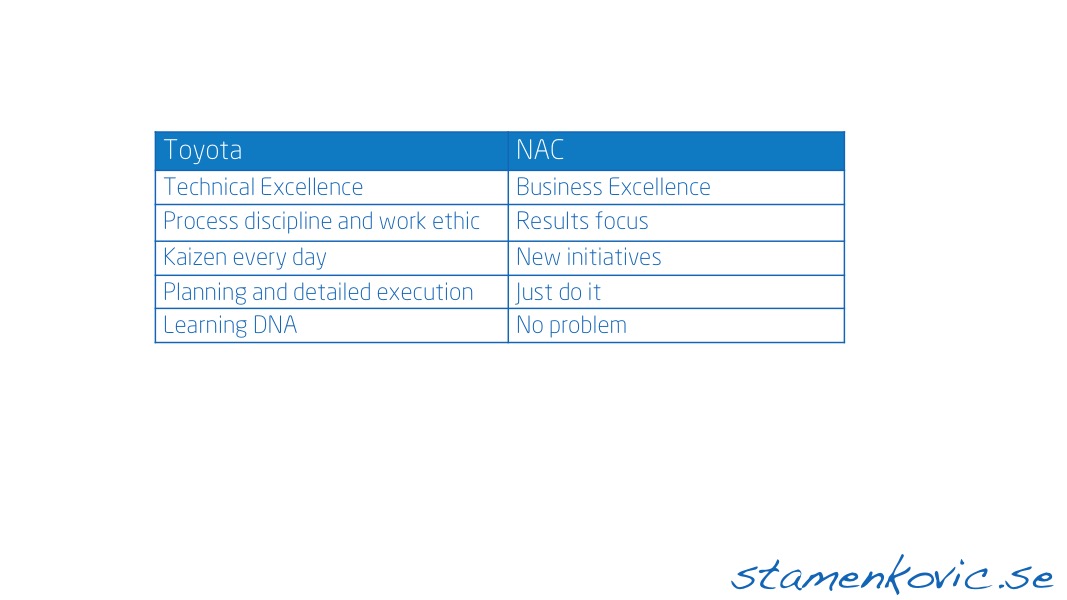

Despite colossal investments of both human and capital resources, most companies have continued to struggle to make organizational learning a true competitive advantage. Once reason is because their focus has typically been on tools that manage explicit or procedural knowledge, which is, although expensive, relatively easy to do, and easy for competitors to replicate. It is in leveraging “tacit” knowledge, or know-how that is the greatest source of competitive advantage. The focus must be on tools that help the organization change the way things actually get done. This type of knowledge is embedded in people and culture; it is around tacit knowledge that the best learning tools and technologies are built and designed.

Toyota strongly believes that the capacity to learn is the main source of competitive advantage and that continuous improvement is about learning. Toyota has two major cultural biases with regard to learning:

Toyota leaders often refer to this learning-by-doing way of thinking as part of the Toyota DNA. Leaders are guides, encouraging and watching for the right opportunities to impart significant lessons.

“TPDS is rooted much deeper in the culture in things like genchi genbutsu, the chief engineer system, kaizen, TPS, etc. it is the totality of it working together in the culture established across many years that makes it all work. What is actually happening in your workplace? A good understanding of that is critical. To have a clear understanding of what your work is and how you are doing, that is what is important.”

Takeshi Uchiyamada, Chief Engineer of the original Prius

An organization’s culture defines what goes on in its workplace, and no company can develop a lean PD system without a strong and vibrant culture.

“The ability to learn faster than your competitors may be the only truly sustainable competitive advantage.”

De Geus (1988)

At Toyota, learning and continuous improvement are fundamental to how each person does his or her job every day and are inseparable from Toyota’s culture. Toyota sets challenging performance goals for every project and holds both real-time and postmortem learning events (called Hansei or reflection) that encourage functional specialists to verify and update their own knowledge database. Learning and continuous improvement are also embodied in a problem-solving process that develops root-cause countermeasures: multiple potential solutions that prevent recurrence. In fact, Toyota’s awesome ability to learn quickly and improve at a regular cadence may well be the characteristic of Toyota its competitors should fear most.