What is waste? Waste (in Japanese muda), this term has become one of the most commonly used terms within today’s global business world. But what is waste.. really? Waste is defined as; “Any activity that does not add value to the customer”. Furthermore, the customer is always the starting point in a lean system, so defining waste starts with defining what a customer values. According to Toyota, waste in product development generally occurs in one of two broad areas:

1. Waste by poor engineering that results in low levels of product or process performance. This is the most destructive waste.

2. Waste in the product development process itself.

Furthermore what is very interesting and needs to be highlighted is that Toyota has managed to “level the flow”, not only by eliminating waste (muda) but also by eliminating “unevenness” (mura) and “overburden” (muri). Battling and eliminating muda does not accurately represent all that “lean” is about. True lean thinking does not focus on one-dimensional muda elimination; it works to eliminate three types of interrelated waste: muda, mura, and muri.

The three M’s

Muda (non-value-added). The best knowned “M”, it includes the seven wastes of the TPS. Any activity that lengthen lead times and add an extra cost to the product, for which the customer is unwilling to pay, are considered muda.

Muri (overburden). In some respects, muri is the opposite of muda. Muri is pushing a machine, process, or person beyond natural limits. Overburdening people can lead to sloppy work resulting in quality problems and potential safety risks. Overburdening equipment causes breakdowns and defects. Overburdening a process means long queues that increase PD lead-time or short-circuiting the process, which leads to downstream errors and rework.

Mura (unevenness). In normal production systems, the workflow is uneven. Sometimes, there is more work than people or machines can handle; at other times, there is not enough work. Engineers are all too familiar with the frenetic pace of work immediately preceding a deadline (for example, prototype review or new product launch), which is generally followed by calm with relatively little work pressure. Unevenness results from an irregular production schedule or fluctuating production volumes caused by internal problems such as computer downtime or missing information. Muda will be a result of mura. With uneven production levels, it will always be necessary to have the equipment, materials, and people on hand for the highest level of production – even if the average requirements are much lower.

Seven Wastes

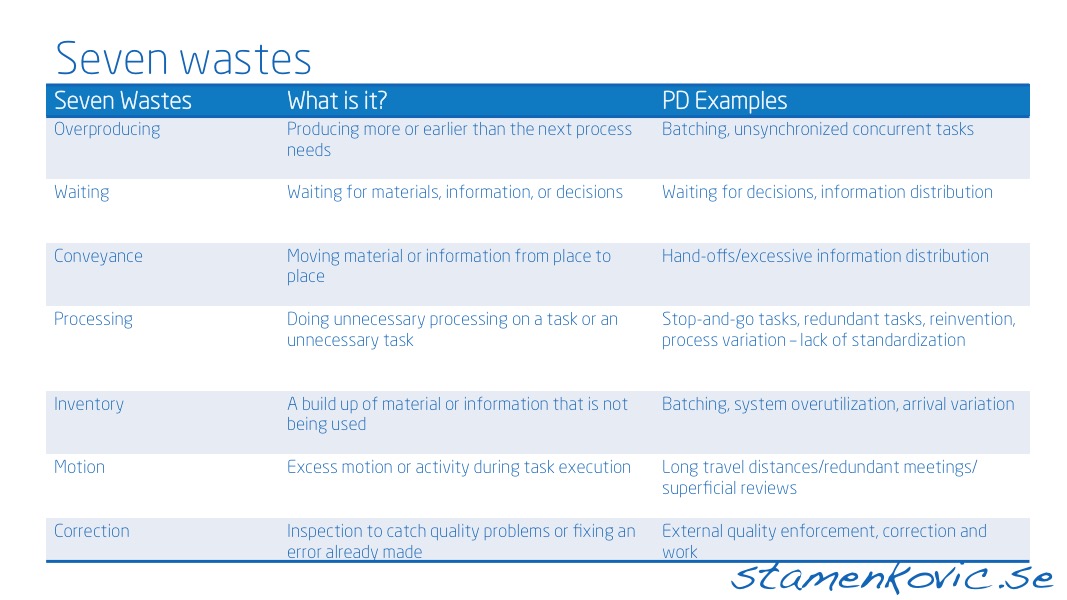

Most product development processes are not lean. They are, in fact, fraught with waste. The starting point for identifying product development wastes is Taiichi Ohno’s seven categories of waste:

Seven Wastes |

What is it? |

PD Examples |

| Overproducing | Producing more or earlier than the next process needs | Batching, unsynchronized concurrent tasks |

| Waiting | Waiting for materials, information, or decisions | Waiting for decisions, information distribution |

| Conveyance | Moving material or information from place to place | Hand-offs/excessive information distribution |

| Processing | Doing unnecessary processing on a task or an unnecessary task | Stop-and-go tasks, redundant tasks, reinvention, process variation – lack of standardization |

| Inventory | A build up of material or information that is not being used | Batching, system overutilization, arrival variation |

| Motion | Excess motion or activity during task execution | Long travel distances/redundant meetings/superficial reviews |

| Correction | Inspection to catch quality problems or fixing an error already made | External quality enforcement, correction and work |