It is important to examine and understand why the seven wastes are so prevalent. It’s mostly because no company truly can understand how to eliminate these wastes until it understands their true root cause. Considering the queuing theory will provide some important insights about the root cause of waste in product development. However, as a reference, traditional product development practices that are particularly problematic include that..

- .. product development working in large batches created by the stage-gate or milestone based product development processes.

- .. product development working with differing levels of capacity at any point in time creating capacity mismatches and resulting in a general ignorance of the capacity and is followed by constant system overburdening.

- .. unpredictable product development workloads expanding to take up all the time of all engineers assigned to projects.

- .. highly cyclic product development workloads characterized by lulls in workload followed by tremendous system congestion, and thereby expanding lead times beyond planned deadlines.

- .. low levels of task execution and scheduling discipline, leading to high levels of both task and interarrival variability.

Laws of Queuing Theory

To gain insight into the reasons wastes are generated by this approach you need to view and consider the product development process as a system; where arrivals (requests for work) place demands upon a limited capacity resource – and apply queuing theory – the phenomena of standing, waiting, and serving. Then consider traditional product development practices of the following basics of queuing theory which are well documented and well understood in manufacturing:

- Law of Batches: Cycle times over a routing are roughly proportional to the (move) batch size used in the routing.

- Law of Variability Placement: Variability early in the routing has a greater impact on WIP and cycle times than equivalent variability later in the routing.

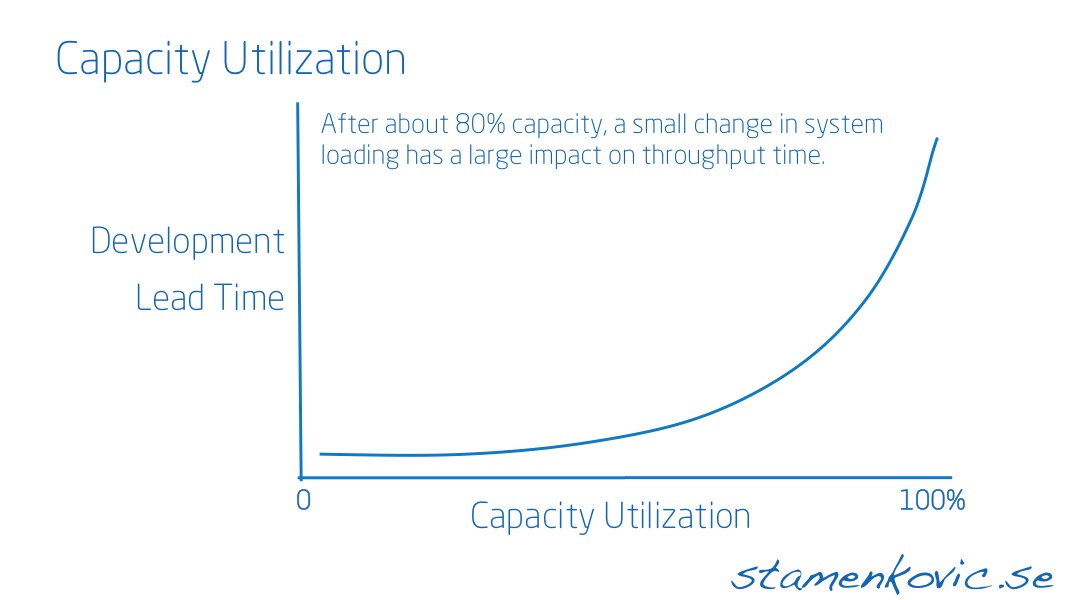

- Law of Utilization: If a system increases utilization without making any other changes, average cycle time will increase in a highly nonlinear fashion.

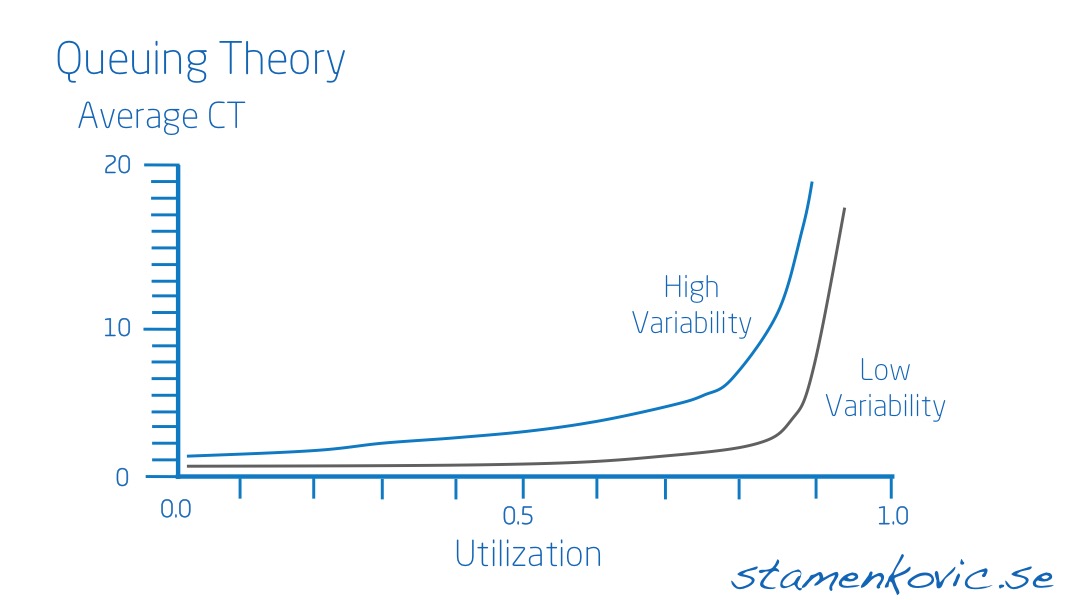

- Law of Variability: In steady state, increasing variability always increases average cycle times and WIP levels.

Capacity utilization

Capacity over-utilization has well understood consequences for system performance yet system capacity is seldom even a consideration in product development planning. The queuing curve illustrates the increases in lead time based on changes in system capacity utilization. It begins to increase in a nearly exponential manner at about 80 percent of capacity utilization, meaning that there is a nonlinear relationship between additional system loading and lead-time increases when 80 percent of system capacity has been reached. Product development systems often operate at levels significantly above this level.

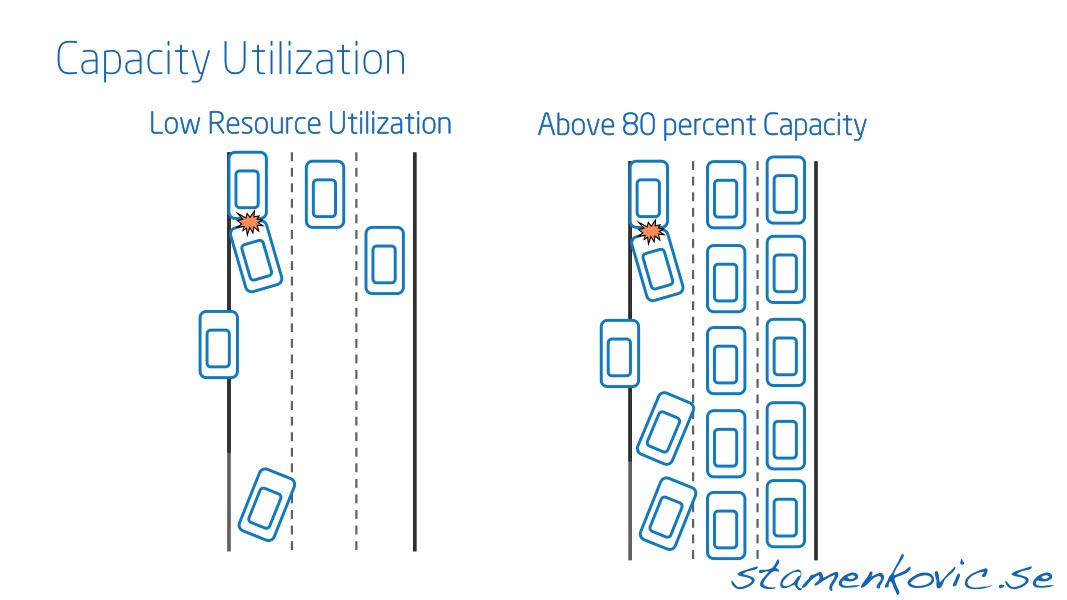

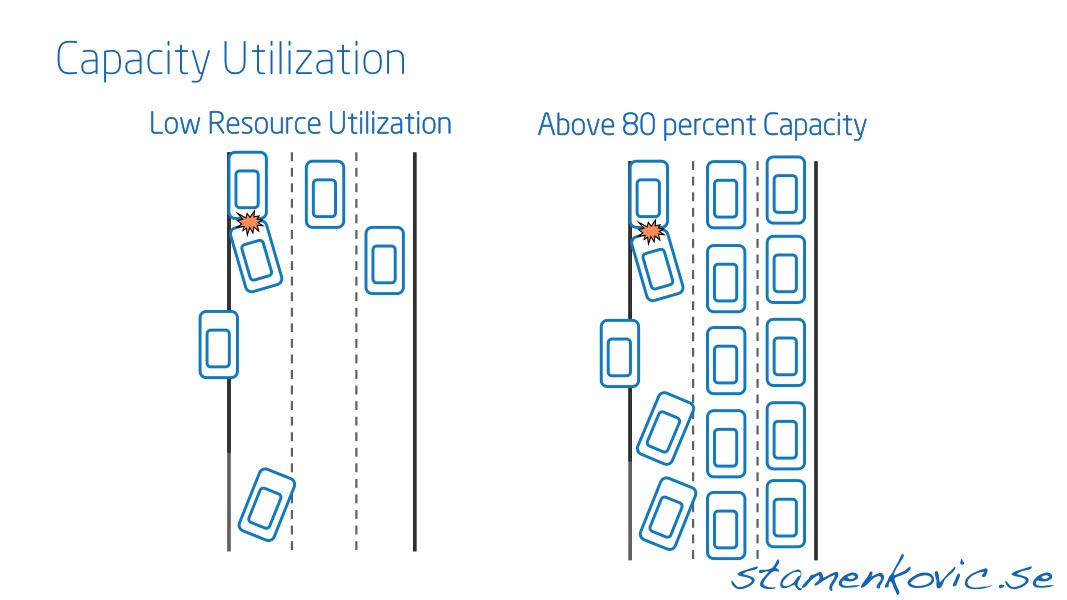

A more familiar and real-world example of the capacity utilization is illustrated with a traffic jam below. When a collision between two cars occurs on a highway, the degree of capacity utilization of the highway will decide if the consequences of a traffic jam will occur. On a low resource utilization (below 80%) highway the chance of a traffic jam is very low, or almost non-existent. On the other hand, on a high capacity utilization (above 80%) highway the chances of a traffic jam to occur are more obvious!

Variation and Variability

To make matters worse, the high level of variability naturally associated with the product development process further exacerbates the system-loading effects (see picture below). Variability is a primary determinant of poor system performance. Unfortunately, most traditional product development systems are ripe with variability. There are two types of variability to be concerned with:

- Task Variability: This refers to differences in the methods and duration of specific tasks rampant in most product development.

- Interarrival Variation: This refers to the time difference between when work is scheduled to arrive at a workstation and when it actually arrives. This is often caused by the first type of variation as well as by capacity constraints.

When these types of variations combine within a system, we get a rapid propagation of variation that is incredibly destructive to system performance. Moreover, if the variability is present early in the process, it will have a magnified effect throughout the process. Thus, any efforts to eliminate this variability on the front end will pay huge dividends. Consequently, managing variability and controlling system capacity is crucial to high levels of product development system performance.

In summary: Companies that continue to view the product development process in the traditional way; as an uncontrollable series of discrete events that just pop up, will always be on the defensive and e forced to deal with variability and capacity issues in a fire drill mode. Toyota never accepts variability problems as necessary or uncontrollable.